Weatherproofing Temperature Sensitive Therapies

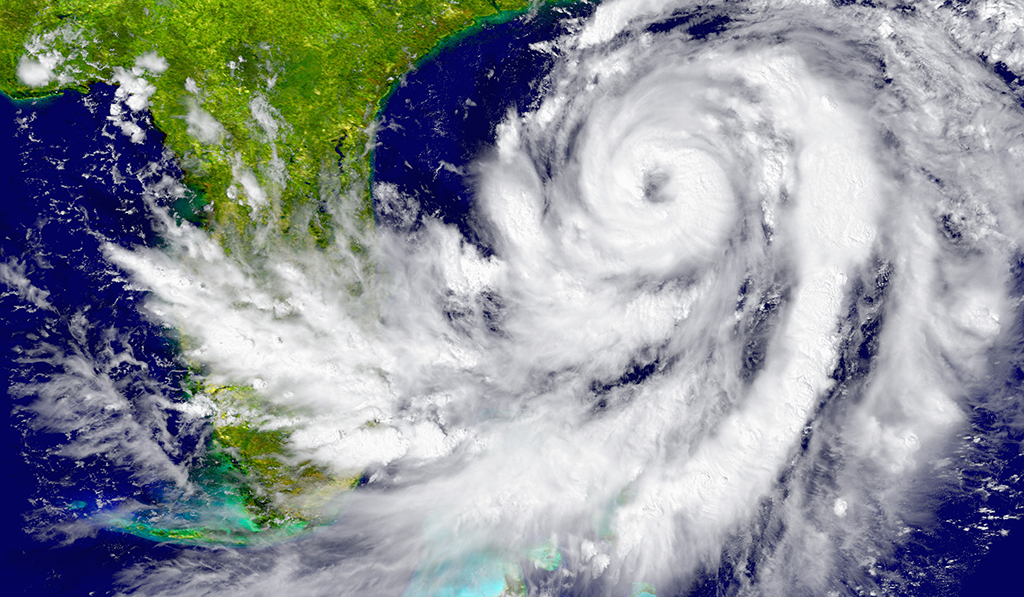

Over the last year extreme weather events have intensified and with dire consequences. From record snow and power grid problems in Texas to deadly tornadoes in Kentucky and wildfires in suburban Portland, these events are destructive and costly. They also put thousands of suppliers and manufacturers at risk.

According to Resilinc’s EventWatch, recent snowstorms across the Southeast and Mid-Atlantic U.S. jeopardized an estimated 25,000 types of products and risked nearly $5 billion in revenue for more than 100 companies.

As our world comes to terms with the effects of climate change and businesses implement sustainability programs to reverse decades of carbon emissions to slow global warming, there must be strategies to deal with the consequences of extreme weather as it is happening today.

Consider the effect of weather on last mile product delivery specifically. Finding out your Amazon package is delayed can be frustrating but realizing life-saving medication is delayed can cause panic for many people. On top of concern over missing a dose, for therapies that are temperature sensitive there can be additional worry that the medication may have experienced a temperature excursion during prolonged transit.

Temperature excursions – too hot and too cold – can lead to problematic changes in prescription medication. And today more than half of all drugs approved by the FDA are temperature sensitive. When a therapy experiences a temperature deviation, potency might be affected, limiting efficacy, while physical manifestations (i.e., particulates) may be reported as contaminants.

When it comes to protecting these cold chain therapies, there are many packaging options available to manufacturers and distributors. When comparing options, the core question to ask has to do with what approach will mitigate the greatest amount of risk. Yet many variables are outside of the realm of control, including weather, carrier response to the weather, lack of truck drivers and ongoing COVID absenteeism. That’s why it is vital to select thermal protection that will outlast and outperform regardless of the source of the delay.

Thermal packaging that is designed to protect clinical payloads for up to 72 hours offers some of the best protection against an unexpected delay. This approach also enables less reliance on overnight delivery or air, reducing expenses associated with logistics. In fact, savvy manufacturers can redeploy savings into the purchase of IoT loggers for added confidence around the stability of the therapy when it arrives at the clinic or patient home.

To learn more about the technologies available to pharma manufacturers and distributors seeking increased delivery confidence, read our recent article in European Pharmaceutical Manufacturer by clicking here.